Usually, customers when ordering mold processing often pay much attention to the price but not much attention to the structure of a finished mold. This problem is really serious and severely affects the plastic injection production later if we have a set of molds that do not meet the necessary standards.

In order to be able to receive orders, many establishments do not hesitate to receive mold processingat a very cheap price to win the hearts of customers, thereby using all means to reduce mold costs by processing methods and substandard components. . When handing over the mold, if the customer often evaluates the mold through the extruded product, but does not pay much attention to the errors of the mold, it leads to the mold receiving the mold for a while, causing errors even though the extruded product meets the requirements.

Notes when ordering mold processing and mold acceptance

In today’s article, the consultant of our mold company will help you understand some notes when placing molds and testing molds to prevent unnecessary risks.

1. Mold texture

Most of the individual or organizational customers who “order mold processing” usually do not have much knowledge about plastic injection molds. Injection molding is an uncommon product and only those who work in this field are knowledgeable about the construction of a complete set of molds. However, you must understand that plastic injection mold construction is a product with specific standards. We recommend reading this article:

Structure and function of parts in plastic injection mold

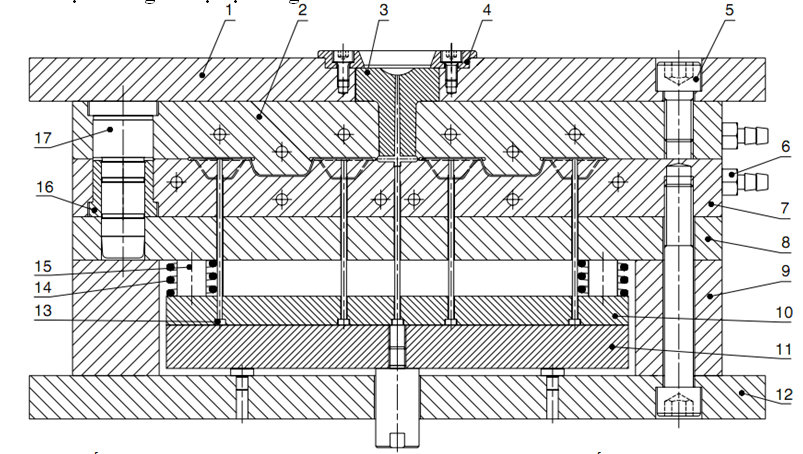

Mold construction has been standardized and used globally. Although each mold factory can be optimized to suit different products, a basic set of molds must have mold plates, a cooling water system or a heating system. mold, product tying system, positioning, guiding, battery return spring…

2. Plastic mold steel

Customers often pay attention to the price but forget to pay attention to the mold steel material. Mold steel has a great influence on mold construction. Cheap mold making units often do not explicitly say or do not mention this issue. Using substandard steel to make molds can help reduce costs, but it also means that the quality of the mold will decrease rapidly with the number of pressings.

It is difficult for an untrained person to distinguish what type of mold steel is, so mold testing is also difficult. Some ordinary steel when tempered will also be difficult to distinguish. Therefore, in order to avoid fraud in this, it should be clearly stated in the contract about the material mold steel. If you are more careful, ask the mold making unit to provide additional documents about the origin of materials such as purchase invoices. You can also consult a material expert when accepting molds.

3. Perfection

Finishing the outside of the mold

- How did you feel when you saw the mold for the first time? If you look at the mold and feel sympathetic, then the mold maker you choose is very careful and pays attention to every little detail. The mold is a mechanical component and usually no one cares about it’s good or bad, but only cares about the work efficiency. However, a set of molds that bring a pleasant look will partly prove the level and skill of the manufacturer.

- Uniformity: The mold is assembled from various mold plates and mold components. A complete set of molds, the mold plates and components when assembled show continuity and mobility. Here you can see if the mold plates are machined squarely, are the mold faces flat or rough, are the mold plates too much apart when assembled, and are the components working properly? ??

- Accessories included: A simple set of molds usually does not have many accessories attached. However, these must-have accessories are: Mold hook, Water line screw, Mold positioning ring, Mold lock clamp… If it is a hotrunner mold, it must come with a temperature controller and electrical cord.

Finishing inside the mold

- Mold surface gloss: Some plastic products require mold surface gloss. To achieve that gloss, the corresponding mold cavity surface is also required to be glossy. If looked at with the naked eye, the surface gloss of the mold cavity must be as smooth as a mirror and no trace of the toolpath left. Our mold company has 2 popular ways to create this glossy surface: polishing or chrome plating the surface. These two methods have different advantages and disadvantages that we will advise customers directly when ordering plastic injection mold processing at our plastic mold processing workshop. With the possession of the most advanced surface treatment technology today, we are proud to bring our customers the most superior product.

- Surface roughness: Some plastic product lines require surface roughness to avoid slippage or fingerprints, so it is necessary to have a method to treat the surface of the mold cavity to create a roughness corresponding to product requirements. Products. There are many common methods for creating roughness such as machine sanding or sandblasting. These two methods have their own advantages and disadvantages that customers will be consulted in detail when placing molds at our mold processing company.

- Logo, braille, watermark: Many products are attached with logos and letters and numbers on the product’s surface to mark the brand as well as limit creative infringement. These elements need to be clearly expressed, sophisticated and unique. There are many methods to process logos, letters, numbers such as CNC engraving, laser engraving, electric firing… With our possession of many specialized and modern machines, our mold processing facility can meet even the highest requirements of customers.

Flexible operation – safe

It is not enough to be beautiful, but it must be used for a long time and safely. When accepting mold, you should test it directly on the press to see that the mold works smoothly and safely. The product retraction system must operate smoothly and efficiently from automatic ejection of product to gentle return to the correct position. The water line system must also be up to standard to be able to keep the appropriate mold temperature while the water does not leak out.

Positions are arranged with guide pins, positioning must match to create continuity when closing the mold and opening the mold. During the opening and closing process, it does not make too much noise…

Conclusion

Above are some issues to pay special attention to when ordering mold processing that you need to know. There are many other issues that we want to advise you more thoroughly, but cannot cover them all within the limit of one article. If you have any questions please contact us immediately.

Mold making is a potentially risky field for both the orderer and the manufacturer. Unlike other available items, Plastic Injection Mold is usually made to order. With each different product, each set of molds will be different. Therefore, the mold making process is similar to the process of making a new product. To produce a satisfactory product, it must go through many stages such as calculation, design, construction, testing and modification, which are full of risks and labor. Our company very much hopes to cooperate with customers on the mutually beneficial aspect. We always try our best to get the trust, support and together we will face difficulties with customers to bring customers the best products.

Contact:

LAM HONG PLASTIC CO., LTD

-Address: No. 21 Street 71, Phu Tan Ward, Thu Dau Mot City, Binh Duong.

-MST: 3702972509

-Hotline: 0968 088 117

-Email: nhalamhong@gmail.com

-Website: www.nhualamhong.com