Every day, we receive many requests plastic mold making from new customers as well as old partners. For customers who have cooperated with us for many years, solving the requirements is quite simple because customers understand the processes as well as the product quality that our company brings.

However, new customers, especially those who order mold for the first time, need to consult more carefully so that customers can fully understand before deciding to order. In this article, we will share some important notes that first-timers who have the need to order molds need to know.

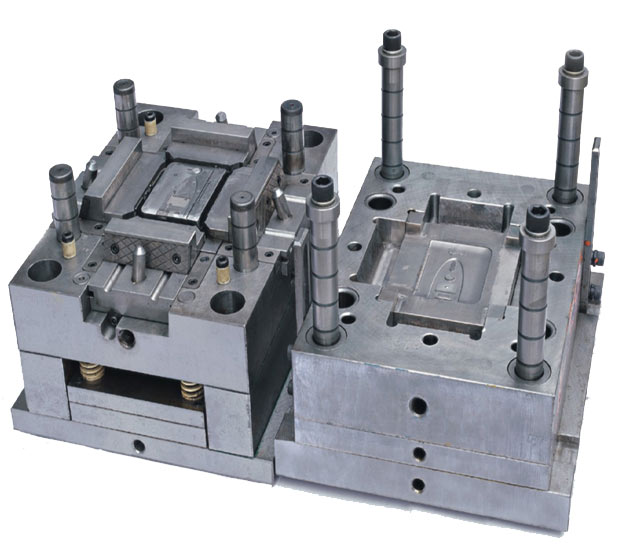

Important notes when ordering mold processing.

Mold quality:

Mold quality is a factor that directly affects the price of making plastic molds that customers have to pay. Depending on the quality that the customer chooses, the price will be high or low. To put it plainly, if a mold is cheap, the quality of the mold can’t be the best. However, the low quality of the mold is not necessarily a cause for concern when this does not affect the purpose of using the product that the customer wants to aim for. For example: If a customer needs to process plastic injection molds to produce a product that is not too demanding in terms of aesthetics, precision or production in small quantities, it is not necessary to invest in a very good set of molds. In this case, if we focus too much on the quality of the mold, it will push up the price of the mold, while the product is sold in small quantities and at a low price, causing damage to the customer.

For products with high requirements for aesthetics, precision and mass production, a quality mold is required. Quality here includes factors such as:

- Precision mold processing

- Mold steel is good steel with high hardness

- The mold structure must be perfect to ensure continuous production without errors…

These requirements require that the mold processing company selected by the customer must have sufficient capacity to meet the requirements of the mold set, and the customer must also pay the corresponding amount.

Product quality

Usually, when a customer places an order for plastic injection mold processing, there are 3 main cases: following an existing product sample, following an existing model but with modifications – further improvement and a completely new product. . All three of these cases have their own notes that customers need to pay attention to.

Order processing of molds for available products

The requirement to make a product according to the available sample is relatively pleasant. The customer gives the sample and the mold processing company only needs to make a mold to squeeze out a quality product according to the sample. Available products are manufactured by injection molding technology, mold making is definitely possible. The evaluation to liquidate the mold handover contract will also be simpler for both the consignee and the mold processing facility.

Order processing of existing molds with further improvement

Customers who want to improve the product need to understand in detail what needs to be improved and it is best to have drawings and documents describing the improvement points so that the mold maker can have a basis for the design and manufacture. mold work.

In case the customer does not fully understand the characteristics of the plastic injection mold but makes a request that is not optimal for plastic mold making, the mold processing facility needs to carefully advise the customer to understand the problems that may arise. born if you follow that improvement. Our company will advise customers in the most complete and detailed way so that customers can understand the characteristics of plastic injection molds.

In addition, we also support product redesign to be able to optimize the product, mold structure as well as the most reasonable mold processing cost.

Order processing for a new product

A new product is a product that has never been on the market. These product lines often arise from customer ideas. Usually customers will order based on 2D, 3D drawings or sketch ideas by hand drawings.

This is the most difficult requirement for mold processing facilities as it requires experience and in-depth knowledge of molds, materials and many other factors. The peculiarity of plastic injection products is that the shrinkage of the plastic will change the size and shape of the product after pressing. Therefore, when making plastic injection molds for requirements like this, the risk is much higher.

For this request, we will use professional simulation tools to predict possible errors in advance to advise customers and offer design and machining options to limit errors. born. Customers also need to clearly understand the necessary requirements of the product such as appearance requirements (gloss, surface roughness…), accuracy (pay attention to the required assembly positions), weight, and volume. … to avoid problems when liquidating the contract and handing over the mold later.

Plastic material

Plastic materials required by the customer to meet the intended use of the product. Here we have primary plastic, which is a plastic that has never been used, and recycled plastic, which is used and then recycled from bottles. Primary plastic makes mold making easier and gives better product quality. There are many types of recycled plastic, so customers need to be careful when using these plastics.

Mass production quantity

Our policy is a lifetime warranty for the molds that customers order to make and order for plastic injection at our plastic injection processing facilities . However, if the customer has a plastic injection machine and only wants to order mold processing , the customer needs to provide information about the total order that is expected to be pressed.

Plastic injection mold is a steel structure consisting of components that interact with each other during operation, so damage over time and according to working intensity is inevitable. The quality of steel and the finish of the mold are two factors that determine the durability of the mold.

In order to ensure optimal mold costs, avoid wasting customers’ money and still ensure to fully meet customer needs, customers need to estimate the total output to be produced and the monthly output so that I advise you to choose the most suitable mold steel.

Delivery time

Customers often want to know the exact delivery time to arrange production plan. Usually a set of molds takes from 2 weeks to 2 months to perfect depending on the difficulty of the product. Most mold manufacturing facilities are late for delivery, even Japanese companies. The problem here is that the characteristics of the mold processing industry are always different from other fields.

Many unforeseen problems arise that are the main cause of delivery delays. To solve this problem, we will anticipate possible risks and come up with a production plan with time to fix the problem if any. Thanks to that, we always deliver on time or sooner if the mold is not defective.

Insurance

It is our company policy to provide a lifetime warranty on our plastic injection molds machined and injection molded in our factory. This means that the customer only needs to pay the cost of making the first table mold and we are responsible for repairing if the mold makes an error during the plastic injection processing at our factory without the customer having to spend extra. any repair costs.

For molds sold outside, our company applies a warranty policy from 3 to 12 months depending on the mold quality that customers want. Customers can also pay extra if they want a longer warranty.

Plastic injection mold repair

All mold lines are processed at our company and are repaired after warranty at a reasonable cost. Our company does not accept to repair molds that are not manufactured by our company unless the customer orders plastic injection at our plastic injection facility.

Maintenance – maintenance of plastic injection molds

In the production process, plastic injection processing, molds need to be properly maintained and maintained to ensure smooth operation of molds, less errors in the production process. We will guide in detail the necessary work for maintenance – maintenance before handing over the mold to the customer.

Conclude

Finding the right mold processing facility and placing an order is a very important job for any customer who needs to make plastic injection molds. New customers who order molds for the first time will try to find a facility that says “cheap plastic injection mold” to do, not “find a quality mold processing facility – the most prestigious. This is really not a smart choice.

The cost you spend on a set of molds is something that is worth wondering and considering. However, plastic injection mold is an asset and it will generate profits for you in the long run. If you try to find the cheapest mold processing facility that accepts poor quality, it may not be profitable for you yet and you have to spend money to repair or worse, make a new set of molds.

Therefore, before deciding to place a mold, you should contact the manufacturer directly for full advice on the issues that we have mentioned above to see how much they can meet. If possible, you should directly visit the factory to see firsthand the products they have made, then make the smartest decision. Good luck.

Contact:

LAM HONG PLASTIC CO., LTD

-Address: No. 21 Street 71, Phu Tan Ward, Thu Dau Mot City, Binh Duong.

-MST: 3702972509

-Hotline: 0968 088 117

-Email: nhalamhong@gmail.com

-Website: www.nhualamhong.com